NEMA FR4

Product Definition:

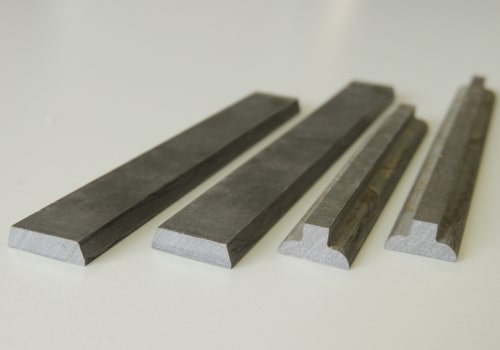

Tufflam FR4 epoxy glass cloth laminate (white/yellow/black) series is a rigid plate-like insulation material made of hot pressing of imported alkali-free glass fiber cloth impregnated with imported epoxy ester resin, and adding imported flame retardants, adhesives, etc.

Tufflam FR4 epoxy glass fiber cloth lamination sheet is a rigid insulating lamination sheet made of composed imported alkali-free glass fiber cloth ,impregnated with imported high quality epoxy resin,added the imported fire retardant and cementing compound,it is a rigid plate-like insulating material under high temperature and high pressure.

Tufflam FR4 black antistatic laminate is an insulating material specially added with anti-static material, and its surface resistivity is < 109, which achieves the function of absorbing electrostatic charge. Tufflam FR4 black anti-static laminated sheet was added specical anti-static material to meet the absorb action for electrostic charge of the insulating material surface resistivity <<109

Advantages

- Excellent Voltage Resistance (electric strength ≥≥16KV/mm)

- Excellent Water Resistance (Water absorption ≤≤ 0.2%)

- Excellent Heat Resistance (Heat resistance above 155 °C) Excellent Heat Resistance (Class F)

- Excellent thermal impact resistance (-273°C to +155°C) Excellent thermal impact resistance (Temp.Index: -273°C to +155°C)

- Excellent mechanical process-ability & high degree of automation processing

- Excellent chemical resistance & radiation resistance

- RoHS, Reach certified products

Applications

Tufflam FR4 laminate is widely used in various switchgear safety partitions, arc extinguishing hoods, arc extinguishing cylinders, arc extinguishing sheets, arc separators, terminal boards, phase insulation, bottom partitions, jump plates, contact support parts; Structural supports for switches and transformers, busbar cleats, etc. Motor armature parts, movable cover plates, slot wedges, fixed mats, thin gaskets, carbon brush holders, etc. In recent years, it has been widely used in consumer electronics, flat panel display, and optoelectronic industries.

Tufflam FR4 laminated sheets are widely used in every kind of switch cubicle such as bursting disk, arc extinguishing chamber, arcing cylinder, arcing piece, flash barrier, wiring board, terminal plate insulating supports; strut parts and bus bar supports in switchgear & transformer; the armature parts of electrical machine such as cover plate, slot wedge, stator , gasket , shims ,carbon brush etc. The epoxy glass fiber laminated sheet series are used much more extensively in consumer electronics, panel display and photovoltaic in recent years

Tufflam FR4 black anti-static laminate is widely used in consumer electronics, flat panel display, and optoelectronic industry in fixture board, production platform, etc.

Tufflam FR4 black anti-static laminated sheets are widely used in consumer electronics, panel display and the fixture board in photovoltaic , production platform etc.

Typical Applications:

- Track Resistance

- Terminal Boards and Tag Strips

- Precision Machined Parts

- Pipeline Insulation

- Mechanical Applications

- Insulating Handles

- Insulating Bushes Spacers Sleeves

- High Voltage Insulation

- Electromagnetic Coil Insulation

- Coil Formers

- Busbar Supports

NEMA FR4 Material Details

Epoxy

| Item | NEMA Grade FR4 Glass Epoxy Laminate | |||

|---|---|---|---|---|

| Description | NEMA Grade FR4 materials are glass fabric reinforced laminates, bonded with flame resistant epoxy resin. At temperatures as high as 130°C, the material maintains excellent mechanical, electrical, and physical properties. Certified by UL, RoHS, and REACH, FR4 from The SAM Group ensures safety, reliability, and consistency. | |||

| Standards | NEMA LI-1: Grade FR4 | MIL-I-24768/27 | IEC 60893: EPGC 202 (sheet) | |

| Availability: | English Units (in) | SI Units (mm) | ||

| Laminate Sheets: | Thickness: | 0.008 to 5.1 | 0.2 to 130 | |

| Standard Size (in mm) | 1220 x 2440 1220 x 2135 |

|||

| Special Sizes Upon Request | 1220 x 2440 | |||

| Standard Color | Green | Yellow | Black | |||

| Convolute Tubing: | FR4 convolute tubes are available from The SAM Group in nearly any custom size of inside and outside diameter, per customer requirements | |||

| Fabricated | The SAM Group custom fabricates insulation material to the exact specifications and drawings of our customers. | |||

Engineering Properties

| Key Characteristics | Test Method | Units | Values |

|---|---|---|---|

| Mechanical Tensile Strength | ASTM D-638 | psi (MPA) | |

| LW | 40000 (275) | ||

| CW | 32000 (220) | ||

| Flexural Strength | ASTM D-790 | psi | |

| Flatwise | 27000 (186) | ||

| Edgewise | 22000 (152) | ||

| Compressive Strength | ASTM D-695 | psi | |

| Flatwise | 60000 (413) | ||

| Edgewise | 35000 (240) | ||

| Rockwell Hardness | ASTM - D785 | M Scale | M111 |

| Deformation & Shrinkage Cold Flow at 4000 psi | percent | 0.25 |

Electrical Characterstics

| Key Characteristics | Test Method | Units | Values |

|---|---|---|---|

| Electric Strength | ASTM D-149 | kV/mm | 16 |

| Dielectric strength perpendicular | ASTM D-149 | V/mil | |

| Short time test | 1/8 in. | 550 | |

| Step by Step test | 1/8 in. | 350 | |

| Impact Strength (Izod) | ASTM D-256 | ft.lb/in | 7 |

| Bonding Strength | ASTM D-229 | lb | 1600 |

| Permittivity | at 1 MHz | 5.4 | |

| Dissipation factor | at 1 MHz | -- | |

| Breakdown Voltage | ASTM D-149 | KV | 45 |

| Comparative Tracking index | ASTM D-695 | CTI | 390 |

| Insulation Resistance | ohm | 2000000 |

Physical & Thermal

| Key Characteristics | Test Method | Units | Values |

|---|---|---|---|

| Specific Gravity | ASTM D-792 | G/cm3 | 1.9 +/- 0.1 |

| Specific Volume | in3 | 14.9 | |

| Thermal Expansion | cm/cm. C | 0.00001 | |

| Thermal conductivity | ASTM D-256 | Cal.cm/s.cm2. C | 0.0007 |

| Specific Heat | cal/g.C | 0.35 - 0.40 | |

| Moisture / Water Absorbtion | ASTM D-570 | % max | 0.1 |

| Temperature Index | NEMA | C | 135 |

| Insulation Class | B | ||

| Flammability | UL 94 | V0 | |

| Convolute Tubing | Yes | ||

| Highlights |

High Mechanical,

Electrical, Electronics

applications. UL94V-0 |

Contact Information

Rex Chambers,

Walchand Hirachand Marg,

Ballard Estate, Mumbai- 400 001

In compliance with RoHS and REACH directives

The information, suggestions, and recommendations provided on our products are based on tests and data that we believe to be accurate. However, it is the sole responsibility of the user to determine the suitability of any material described herein for their intended use, the manner of such use, and whether the use infringes any patents. We make no warranty, expressed or implied, including but not limited to warranties of merchantability or fitness for a particular purpose.

It is important to note that we shall not be liable for any incidental or consequential loss or damage resulting from the use of our products. We strongly recommend that users perform their own tests and evaluations to determine the suitability of our products for their particular purposes.

Leave a Message

If you are interested in our products, please feel free to contact us!or send email to us!Email Address:sales@samcomposites.com

How we can help you!

If you are interested in our products, please feel free to contact us!

Contact us